Purpose of a slurry acidification system

The acidification of slurry is in agriculture – among others, according to the European Regional Development Fund – the most efficient and cost-efficient technology for reducing greenhouse gases and for nutrient recovery.

The main advantage of the acidification of slurry in the stable is that the greenhouse gas emissions from the stable stage are immediately reduced.

Then also in the months of storage as well as during the spreading, further evaporation will be avoided and this thus has a sustainable and efficient emission-reducing effect on the entire emission chain of the nutrients. The reason for these high greenhouse gas emission reductions is simple: If we can acidify and completely neutralize all fresh dejections from livestock within a few minutes (even seconds) – by lowering the pH – these dejections are hydrochemically stabilized and, until to be absorbed by the plants, no longer susceptible to being able to evaporate again under any form.

It is known that what does not evaporate from the raw slurry remains in the nutrients. And this happens – from a scientific point of view – regardless of how and how long the slurry is stored, how much it is diluted, whether the repository is covered1 or not, how it is spread1and what the soil properties of the agricultural areas of a farming unit are.

1: Respect legal requirements. Scientific knowledge does not necessarily and / or automatically adapt legislation According to (OAPC) – as of January 2022 – it is mandatory to cover open slurry storage facilities throughout Switzerland. The specific statutory provisions of your canton of residence apply to the spreading of slurry.

Advantages of a slurry acidification system

Achievement of a relevant ammonia emission reduction within the scope of a building permit procedure

Receipt of specific investment aid for structural measures and facilities for the realization of ecological goals (contributions, especially for slurry acidification plants, available from 2021 and on)

Could make the mandatory cover of open repositories1 superfluous

Increasing fertilizer efficiency and lowering the acquisition costs of other fertilizers

Reducing odors around farms

Operation of a fully automated slurry management system (less work and more safety)

Increase in operating income through CO2 compensation (sale of CO2 certificates)2

1: According to (OAPC) – as of January 2022 – it is mandatory to cover open slurry storage facilities throughout Switzerland.

2: This approach is under development, but is unfortunately not yet operationally available – on the Swiss market – today.

The investment aid for structural measures (cantonal investment loans) and facilities for the realization of ecological goals as well as for meeting the requirements of homeland and landscape protection (Federal Subsidies Ordinance FSO) create support throughout Switzerland of up to 75% of the total acquisition costs of such a slurry acidification plant. Gladly you are welcome – with the following simulation model – to carry out your operating calculation with regard to ammonia volatilization:

Sustainable development from which everyone Involved can benefit and grow – in the form of an economic, ecological and social return. This is what we stand for!

For people, your livestock and our environment

Systems / construction types

The processing system in cattle stalls differs significantly from that in pig stalls. We therefore speak of a “canal system” in cattle farming and a “flush system” in pig farming.

In addition, a processing process for farms with mixed animal husbandry was specially developed for Switzerland, in which the said “canal system” and the said “flush system” are combined, but are always operated separately from one another.

In the design, all types of systems are operated with an organic or inorganic acid, whereby they contain all standard components as well as their own software for controlling and monitoring the treatment process. This means that the slurry management – from the stable to the final storage – runs completely self-reliantly all year round and thus a lot of work is saved.

How it works

The hydrolytic enzymes (i. e. urease) formed by bacteria in the feces begin to break down the urea molecules directly, depending on the pH value and weather conditions. This process is known as “hydrolysis”. The urea contained in the urine is split into ammonia and carbon dioxide with the help of water and then evaporates in the atmosphere, where it becomes a harmful greenhouse gas. Greenhouse gases are gases that absorb and emit radiation energy in the thermal infrared range and thus cause the greenhouse effect. This effect in turn is responsible for the temperature on the earth’s surface.

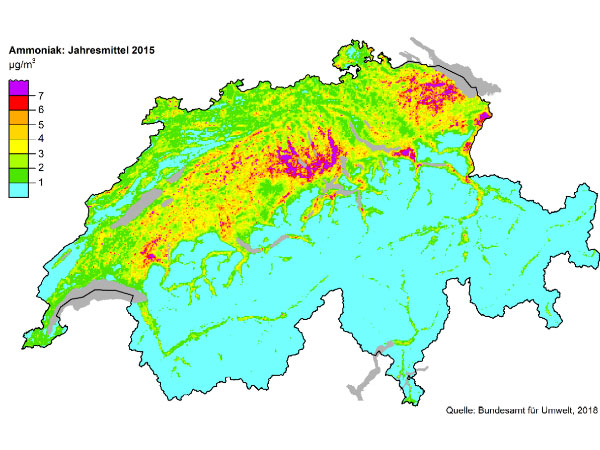

Ammonia emissions in detail

In summary, it can be stated that Switzerland ranks second behind the Netherlands in terms of proportional ammonia emissions and that around 60’000 tons of ammonia gases are produced in Switzerland every year. 92% of these come from Swiss agriculture. The proportion of these ammonia emissions, which are generated exclusively in animal husbandry, is approx. 93% and that in plant cultivation approx. 7%. The emissions from animal husbandry are as follows:

41 % running areas in the stables as well as exercise yards

33 % spreading slurry

10 % storage of slurry

7 % spreading manure

6 % storage of manure

3 % pastures

The individual animal species cause the following different emissions:

78 % cattles

12 % pigs

6 % poultry

4 % other animals